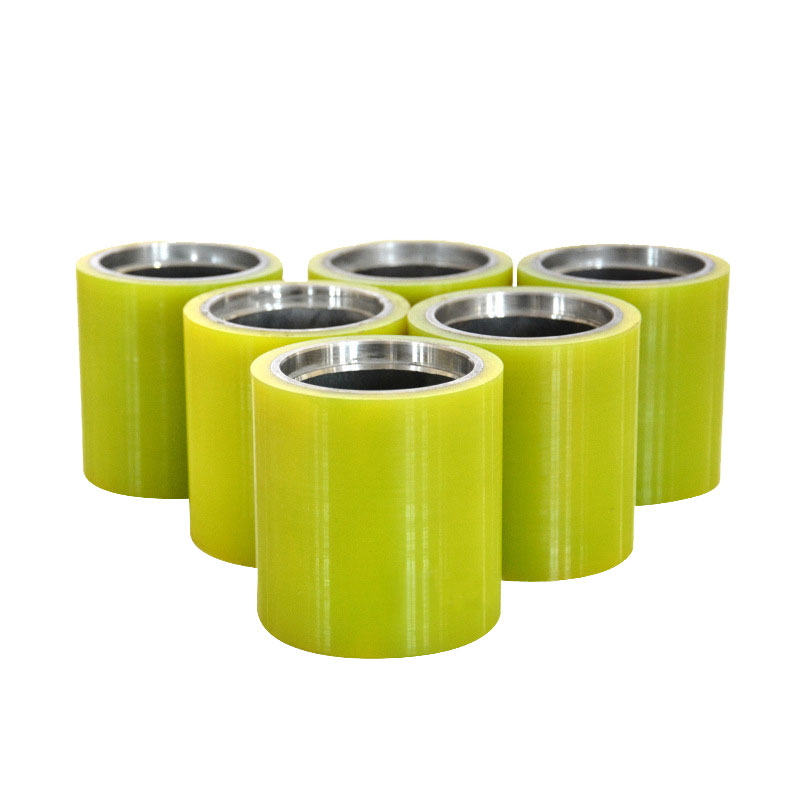

Custom Polyurethane Rollers

- Min.Order QTY: 100 piece

- Packaging: Carton or Plywood Box

- Delivery Time: 15 Working Days

- Port: Shanghai/Ningbo

- Payment Terms: T/T,Western Union,Paypal

- Specifications

Custom Cast Polyurethane Rollers

High quality polyurethane roller with excellent performance including high load capacity, shock absorption, noise reduction, low rolling resistance and compression resistance during operation. Cast urethane roller with beautiful appearance and are especially resistant against impact and abrasion.

Custom urethane roller is cast liquid polyurethane elastomer material into a mold, and then Put the polyurethane with mold to be cured in the oven. frequently are cast oversized to allow for machining to your specific size and tolerance.

Custom Urethane Roller For Your Application

As the key parts of material handling systems and machines, polyurethane rollers are used more and more widely, include:

- Rollers Conveyor equipment

- Logistics Conveyor System

- Diverter Rollers on Package Handling Systems

- Rollers on Paper and Plastic Slitting Equipment

- Labeling Machine Rollers

- Driver Rollers in Lumber Cutting Machinery

- Mining machine

- Glass Conveyor

Material Properties for Custom Polyurethane Rollers

| Hardness (+/- 5) | 40A | 55A | 70A | 80A | 90A | 60D |

| Ultimate Elongation (%) | 640 | 540 | 540 | 640 | 500 | 300 |

| Ultimate Tensile (PSI) | 3200 | 5300 | 5600 | 6900 | 6200 | 6400 |

| Tear Strength, pli Die “C” | 150 | 244 | 332 | 421 | 568 | 620 |

| Split | 19 | 51 | 92 | 175 | 134 | 125 |

| Compression Modulus | 380 | 830 | 1660 | 1990 | 6460 | 16200 |

| Compression Set (% 22 Hrs. @ 158ºF) | 0 | 1 | 7 | 16 | 18 | 30 |

| Bashore Rebound (%) | 50 | 41 | 37 | 31 | 35 | 52 |

| Abrasion Loss, mm | 200 | 224 | 159 | 94 | 101 | 115 |

The process of Custom Urethane Rollers:

- core design and manufacturing. Most of our clients have roller designs that include a metal core.We utilize many different machining technologies to provide economical roller cores in a wide range of size, tolerance requirement, and Bores or shaft bearing journals tend to be the most tightly toleranced feature of any roller core.

- Steel core processing, sandblasting, cleaning, gluing;

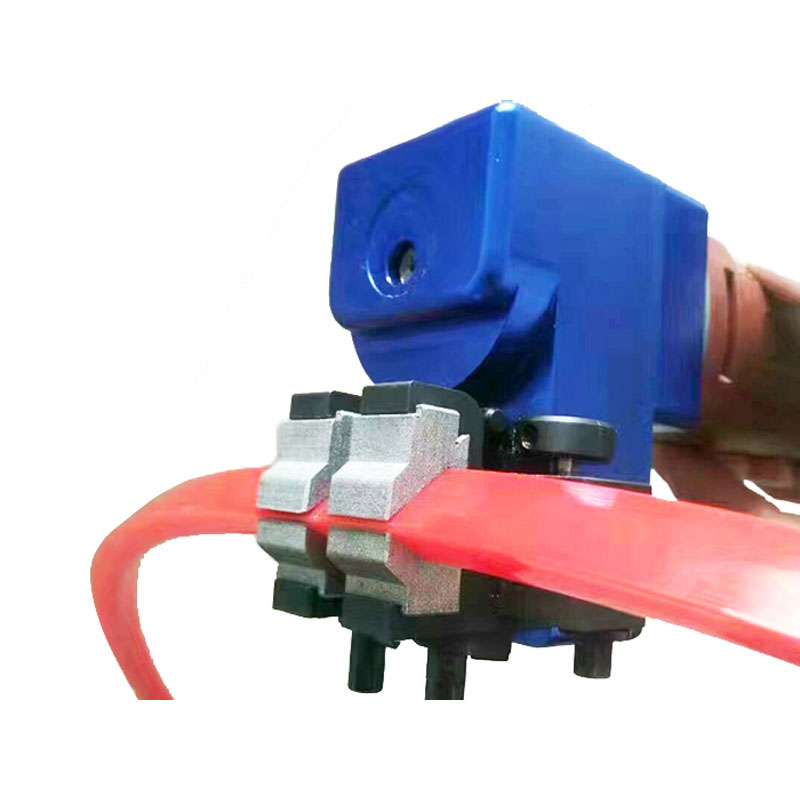

- Hand cast or machine cast polyurethane layer.

- machining urethane roller, grinding and truning ,and secondary machining operations which allow us to groove, chamfer, radius & tap as request, precision rollers request to control of outside diameter and concentricity tends to be the major focus at this stage.

Polyurethane Roller Types What We Custom

- Drive Roller and idler rollers

- V-Groove and U-Groove rollers

- Transfer, feed and nip rollers

- Wire Guide Rollers

- Soft-hardness rollers and more

If you would like to know more about polyurethane rollers and wheels or would like to request a quote for custom polyurethane Rollers, please don’t hesitate to contact us! We have a team of experienced engineers to help and guide you from concept to solution.

Tag:Cast Urethane Roller , custom polyurethane rollers , custom urethane rollers , urethane rollerDevelop & Produce Polyurethane Products

We focus on the needs of all our customers and continue to develop innovative products based on our experience and expertise. This allows us to continuously expand our product line to meet the needs of different customers.

Pulisen have the capability and facilities to produce any kind of Urethane product from 30A to 75D, in any shape, size or color.at the same time,we can custom polyurethane products from your drawings or sketches to meet your industrial application.

- Most of our standard products are in stock for fast delivery

- If you are in need of a custom cast urethane products,contact us today for more information,we will be happy to assist you.